LHRHA – LABORATORY OF HYDRAULICS, WATER RESOURCES AND ENVIRONMENT

The Laboratory of Hydraulics, Water Resources and Environment (LHRHA) is one of the laboratories of the Department of Civil Engineering, Architecture and Environment, having as main activities Teaching, Research and Development (R&D) and Specialized Consultancy in the domain of Hydraulics of open channel and pressurized-pipe flows. Its area is approximately 670 m2, resulting from the merge of two laboratories: the Laboratory of Hydraulics, with a larger area (570 m2), and the Laboratory of Environment, with a smaller room (100 m2).

The Laboratory of Hydraulics has the largest experimental facilities comprising flumes and pressurized pipes, fully equipped with state-of-the-art instrumentation for developing laboratory and field tests (e.g., particle image velocimeter, PIV; particle tracking velocimetry, PTV; acoustic doppler velocimeters, ADV; ultrasonic velocity profilers, UDP; electromagnetic and ultrasonic flowmeters; pressure, torque, temperature, conductivity and rotational speed sensors; laser and micro-echo-sounders). Most relevant facilities are the morphodynamics of river flume, the confluences flume, the mechanics of granular media in 3D turbulent flows flume, the hydraulic structures and pool-type fishways flume and the armour blocks stability on rubble mound breakwater flume, as well as several pressurized pipe circuits, made of steel, copper, polyethylene and acrylic, for the study of phenomena associated with hydraulics transients (e.g. effect of air pockets, cavitation, pipe wall viscoelasticity and leak detection) and for testing small-hydropower machines (pumps, turbines, water wheels). The laboratory also has multiple hydraulic benches (e.g., friction and local head losses, momentum flux, free and forced vortices, pumps, turbines, weirs, Reynolds experience, flow visualization, percolation) and a flume for teaching open channel flows at the Bachelor and Master levels. Several competitive research projects (national and international) are developed using existing and specially assembled facilities, in several of the referred domains of Hydraulics and many master and doctoral projects with experimental analysis are also conducted in this laboratory in the scope of the Civil Engineering, Environmental Engineering and Mechanical Engineering courses.

The Laboratory of Environment supports environmental engineering and hydrogeology activities. It accommodates experimental constructed wetland beds, an LSS respirometer, a green wall for greywater treatment, and an installation to analyze sulfide release on drops in wastewater drainage systems. It also has technical equipment for monitoring water, soil, biological analysis, and field data.

MAIN ACTIVITIES

- Teaching Activities

- Research and Development (R&D)

- Specialized Consultancy

MAIN RESEARCH AREAS

- Pressurized water systems

- Fluvial hydraulic structures

- Environmental fluid mechanics

- Coastal morphodynamics and coastal and port structures

- Green wall for grey water treatment

- Hydropower solutions based on novel energy converters

- River restoration and management

- Sediment transport and river morphodynamics

- Constructed wetland

RESEARCH & DEVELOPMENT ACTIVITIES

- Fluid-structure and air-water interaction during hydraulic transients

- Morphodynamics of river confluences and diversion channels

- Hydropower and efficiency in water systems

- Hydrodynamics of turbulent flows within vegetated boundaries conditions

- Wastewater treatment and reuse

- Current density analysis in porous media

- Hydropeaking and shelter configurations on the behavior of fish

- Mechanics of granular media in 3D turbulent flows

- Local scour at complex bridge piers

- Clogging process in constructed wetlands

- Biofilm growth measurement

- Support of Ph.D. and MSc thesis experimental work

CONSULTANCY ACTIVITIES

- Slit check-dams for the mitigation of debris flows

- Morphodynamics of river confluences

- Evaluation of infiltration inflows

- Evaluation of surface and groundwater quality

- Small turbomachines testing

- Mechanics of granular media in 3D turbulent flows

- Reclaimed water testing

MAIN EQUIPMENT

TEACHING CHANNEL

This is an acrylic channel 1.22 m long, 0.10 and 0.21 m high, and 0.075 cm wide for the study of hydraulic structures. Main equipment and instrumentation: Water reservoir; KROMM brand pump; type KRM 15; flow rate between 8-35 l/min; and maximum lifting height of 39 m.

HYDRAULIC STRUCTURES CHANNEL

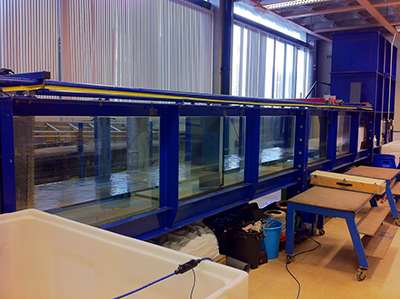

This is a 8m long, 0.70 m wide and 0.80 m high horizontal flume, with glass side walls, equipped with flap gates immediately up and downstream the flume.

CRIV: RECIRCULATING AND TILTING HYDRAULICS FLUME

CRIV is a 12.5 m long, 0.41 m wide and 0.50 m high prismatic glassed walls channel with adjustable slope. It includes a water and sediment recirculation circuit.

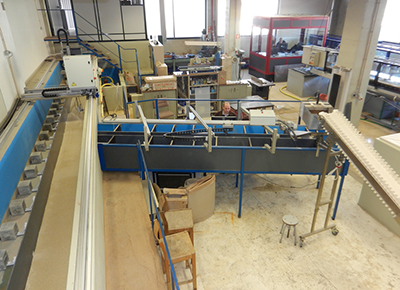

CONFLUENCE CHANNEL

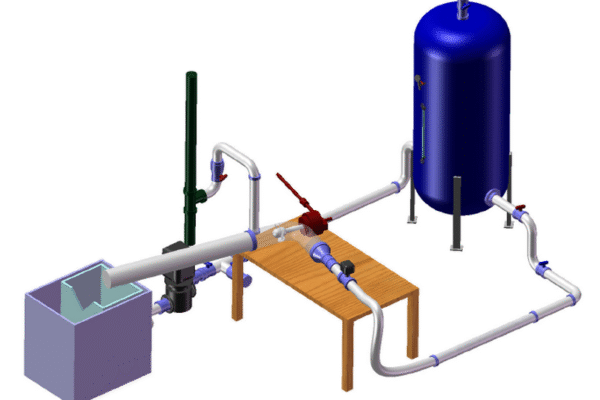

It includes the main channel (MC) and a tributary channel (TC). The MC is 10.0 m long, 1.00 m wide and 0.70 m high. The TC is 4.0 m long, 0.50 m high and adjustable width. It is equipped with conveyor belts for feeding and an automated transverse system.

STEEP SLOPE FLUME

This is a 3.50 m long, 0.50 m wide and 0.50 m high steel flume with adjustable slope up to 26.5%. It includes a water recirculating circuit and it is equipped with a hopper and a conveyor belt for coarse sediment feeding.

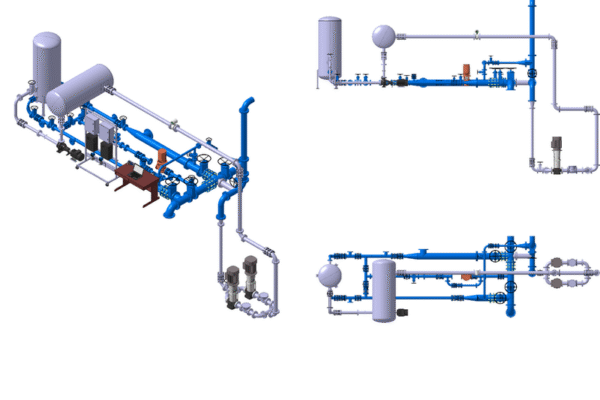

TEST-RIG FOR SMALL-POWER PUMPS AND TURBINES

Closed reversible circuit composed of steel pipes with diameters between 50 and 200 mm for testing small-power reaction turbo machines in transient and in steady state conditions Fully instrumented and equipped with a state-of-the-art data acquisition system.

WATER HAMMER TEST-RIG I

Copper pipe coil with 103 m and 20 mm diameter, with a centrifugal pump and control valves. Developed for measuring hydraulic transient pressures generated by pump’s trip-off and valve’s manoeuvres. Fully equipped for a

WATER HAMMER TEST-RIG II

Straight pipe, 15 m long, 20 mm diameter for measuring transient pressures generated by valve’s manoeuvres. Fully equipped for acquiring high frequency hydraulic and mechanical properties.

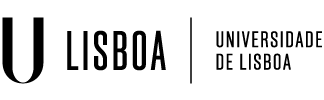

COMPRESSED AIR VOLUME SYSTEM

Compressed air volume system (CAV) to study the behavior of entrapped air during pipe filling and under transient conditions. This system is composed of two hydro-pneumatic vessels, one CAV, a pump with maximum nominal head of 28.2 m and nominal power of 4 kW and control valves.

PIV – PARTICLE IMAGE VELOCIMETRY

PIV (Particle Image Velocimetry) is a laser based technique to acquire velocity fields at a maximum frequency of 15 Hz, composed of a 1600×1200 CCD camera synchronized with a 30 mJ, 532 nm laser.

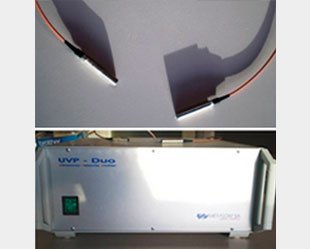

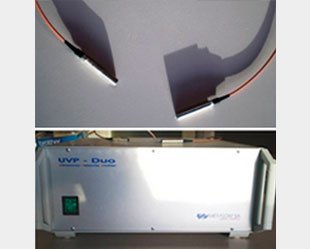

UVP – ULTRASONIC VELOCITY PROFILER

UVP: acoustic probes for measuring velocity profiles and water and bottom levels; composed of 1 UVP system with 2 probes of 2 MHz and 4 MHz.

LIMNIMETER

Limnimeters: 10 ultrasonic distance measuring sensors UNDK30U6103/S14 with sensing range 100-700 mm, repeatability < 3 mm and response time <5 ms. Used to measure bed and water surface levels.

MINI-ECHO-SOUNDER

Two Mini-Echo-Sounders (UltraLab UWS) to measure bathymetry, erosion and sedimentation without emptying the model. It measures distances in water from 2 cm up to 15 m with 1 mm-accuracy and 1 MHz-acquisition rate.

TP5B – FIVEBLADE TUBULAR PROPELLER

TP5B was design at LH to study the efficiency of micro-energy production with a maximum turbine flow of 12 l/s. The installation of micro turbines is particularly attractive for water supply systems.